torsion test experiment theory|torsion experiment lab report : agencies Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .

Resultado da Bola Branca 20h7. Bola Branca 20h7. 40 min. playlist_add. Sep 29, 2023. Bola Branca 18h16. Bola Branca 18h16. 8 min. playlist_add .

{plog:ftitle_list}

Big Cock Trans Porn Videos. HD 4K VR. Trending Newest Best Videos Quality FPS Duration Production. Clear filters. Big Cock Tranny cams. Big Cock Shemale .

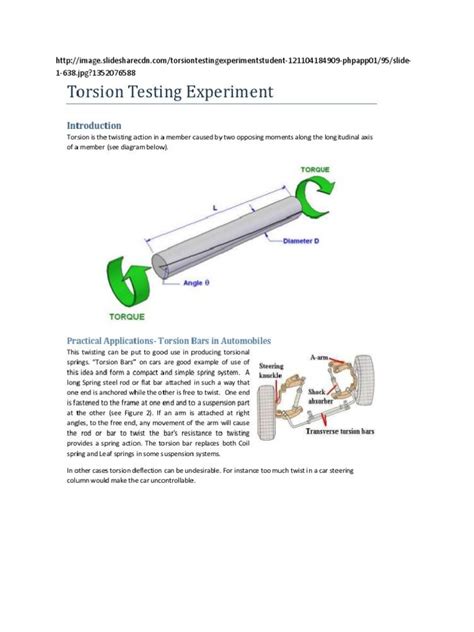

In this experiment, solid cylindrical specimen of steel or brass will be subjected to a torsional load. The test will be conducted until failure (i. it will end in the fracture). During the test, the . The experiment aims to verify the torsion formula and measure G for each material by testing specimens of varying lengths and loads. This experiment examines how shear forces vary with increasing point loads .ME 354 LAB #4: DISCUSSION OF THE TORSION TEST. Each lab section performed a torsion test of a cylindrical 6061-T6 aluminum specimen. The specimen was mounted in a Technovate . Torsion testing involves the twisting of a sample along an axis and is a useful test for acquiring information like torsional shear stress, maximum torque, shear modulus, and .

Background and Objectives. Understanding how materials react to an applied load is essential for engineers to design structures that are both safe and effective. While there are many different .

Torsion testing predicts a material’s behavior under twisting forces by assessing key properties such as torsional strength, shear modulus, yield strength in torsion, ductility, and brittleness. It enables the understanding of fatigue behavior, .

• When subjected to torsion, every cross-section of a circular shaft remains plane and undistorted, because a circular shaft is axisymmetric. • Cross-sections of noncircular (non-axisymmetric) .Torsion Testing of Structural Metals Standards • ASTM E143: Shear Modulus at Room Temperature Purpose • To determine the shear modulus of structural metals Equipment • .

Example 19.1. A torsion-bar spring is loaded with F = 35 N and T = 8 N.m. The material is cast iron with Sut = 207 MPa and Suc = 723 MPa. Determine a diameter d using a factor of safety . Theory Torsion Test. MICROBIOLOGY DEPARTMENT Laboratory User Manual. STRENGTH OF MATERIALS TORSION TEST (1) Microbiology Laboratory Manual Questions Summary. To conduct torsion .Figure (1): Diagram of Torsion Test Setup with Measurements . 3 The image above displays the location of the strain gauges: in approximately the center of the torqued . Before beginning the experiment, the position transducer was calibrated. With blocks stacked on top of each other, we recorded the position transducer’s outputted voltage at .

safe. The torsion test continues until the specimen fails so that students can examine the fracture surface and determine whether the failu re mode is ductile or brittle. Experimental Results and Discussion Torsion tests were conducted on 2024-T 351 aluminum alloy specimens using both IG measuring techniques.Torsion Test • Not as common in testing as tensile test. • Torsion test samples (similar to tensile samples). • But also used on full sized parts such as shafts, axles, drills etc. Troptometer Torsion machine • Torsion machines use an electrical motor and gear drive to apply a torque to the specimen • The specimen is gripped on both ends, The theory of torsion experiment is a scientific experiment that studies the behavior of a rotating body in a gravitational field. It is based on the idea that a body rotating in a gravitational field will experience a torque, or twisting force, due to the gravitational field. . The conclusion of a torsion test experiment is that the material .Theory Procedure Self Evaluation Simulation Assignment . IS 1717 (2012): Metallic Materials - Wire - Simple Torsion Test, Third Revision, 2012; Community Links Sakshat Portal Outreach Portal FAQ: Virtual Labs. Contact Us Phone: General Information: 011-26582050 Email: [email protected] .

A torsion test is a mechanical testing method that evaluates the properties of materials or devices under stress caused by angular displacement. During a torsion test, a specimen is subjected to a twisting or torsional force, which induces a torque. This test is used to measure various mechanical properties of materials, including their modulus of rigidity, shear stress, .m) or foot-pound force (ft

Using the torsion testing machine, we will find out modulus of rigidity and shearing property of mild steel specimen. Main objective of torsion testing experiment is following, To find modulus of rigidity of test machine. To draw torque (T) Vs Angle of Twist (θ) Curve. To find Breaking Torque and shearing stress.

Cavendish's diagram of his torsion pendulum, seen from above. The pendulum consists of two small spherical lead weights (h, h) hanging from a 6-foot horizontal wooden beam supported in the center by a fine torsion wire. The beam is protected from air currents inside a wooden box (A, A, A, A).The two large weights (W, W) attached to a separate suspension attract the small .

In a torsion test, a test specimen is twisted to a specified angle with a predetermined force, or until failure occurs. . This experiment focuses on torsion testing on steel, brass, and aluminum. . The conventional theory of torsion assumes that after twisting, plane parts would stay plane. The circular segment is the only one that . The final characteristics acquired after the torsion test include Modulus of Rigidity, maximum Shear Stress, maximum Torque, and Angle of Twist, and how the material responses in each case, are elaborated in the article using tables and graphs. The mathematical computation is demonstrated in order to validate the data received during the test.

2000 jeep cherokee sport 4.0 compression test

Torsion testing of basic grade mild steel with an axial torsional testing equipment is one type of test used to assess the torsional characteristics of the structural material. 2. Torsion: Torque applied in a plane perpendicular to the longitudinal axis of a member is called as torsion. 3. Difference between Torque and Moment: 4. Twisting Moment: It is the summation of torque either left or right of the section. 5. Bending Theory: 6. Torsion Theory: Assumptions: Material is homogeneous. Circular section remains .

EASTERN MEADITERRANEAN UNIVERSTY DEPARTMENT OF MECHANICAL ENGINEERING LABORATORY HANDOUT COURSE: STRENGTH OF MATERIALS (MENG 222) COURSE: Strength of Materials MENG222 .This torsion test experiment is carried out on rods made of mild steel which is a standard torsion application instrument with in diameter 0 and 0 in length. The rod is connected to a machine that measures torque at one end, and the other .Experiment Two- Torsional test Experiment Two (2) Torsional testing of Circular Shafts Introduction: Torsion occurs when any shaft is subjected to a torque. This is true whether the shaft is rotating (such as drive shafts on engines, motors and turbines) or stationary (such as with a bolt or screw).Torsion Only: Applying only torsional loads to the test specimen. Axial-Torsion: Applying both axial (tension or compression) and torsional forces to the test specimen. Failure Testing: Twisting the product, component, or specimen until failure. Failure can be classified as either a physical break or a kink/defect in the specimen.

Angular speed control is the type of experiment we will be doing, thus the directly measured quantity in this experiment will be torque. THEORY Notation Symbol Description Units A Area m2 M Applied Moment Nm F Force N L Total Length of a specimen m L Test Length m T Torque Nm J Polar Moment of Inertia m4 G Shear Modulus Nm-2 Introduction To put meaning to the data and conclusions drawn in this experiment several things must be known about the materials tested and the theory behind torsion testing. The two materials tested, cast iron and mild steel, have opposing characteristics. Steel is classified as a ductile material, a ductile material is known to be able to experience very large .The objectives of the torsion experiment include determination of shear modulus of elasticity . In the torsion test, a torque “T” is applied to one end of a circular cross-section metallic rod while the other end is held fixed in a stationary grip. We use a bench-mounted Tinius Olsen 10,000 in-lb Torsion Tester shown in Figure 1.

6. Set speed to ~ 5°/min, zero the torque and start test (figure 1.2.4). Figure 1.2.4. Torsion controls. Structural Metals Lab 1.2 53:086 – Spring 2008 The University of Iowa 11 . Theory Discussion If you are really observant and compare this experiment to the tensile test, you .

torsion test pdf

a) Comparative stress-strain relationships of low carbon steel and aluminium alloy and b) the determination of the yield strength at 0.2% offset .3 Ultimate Tensile Strength, σ TS Beyond yielding .Experiment Details Two specimens were used for this experiment: 6061-t6 aluminum, 1018 Cold rolled steel. The experiment is placed under Torsion Test Machine, based on igure 1. Measurements of the Machine were taken for later to calculate for experiment torque. Iniial measurement of the specimen needs to be taken down before the experiment.Torsion Test 8. Compression Test III– CYCLE . Experiment No. 2 VICKERS HARDNESS TEST . Theory: It is similar in principle to Rockwell hardness test, but utilizes a different indentor and different magnitudes of loads. The indentor used is .

2000 jeep cherokee sport 4.0 compression test from the manual

2000 jeep grand cherokee 4.0 compression test

2000 jeep grand cherokee compression test

2000 jeep grand cherokee laredo compression tester

Academia Reentry. April 2, 2018 ·. Aqui na Reentry você faz o plano anual e tem o 13º mês GRÁTIS! A gente te paparica, sim! Entre em contato e saiba mais. #academia #saúde .

torsion test experiment theory|torsion experiment lab report